Notre longévité et notre liste de références, témoignent de la qualité de nos appareils et de la confiance que nous témoignent nos clients.

La maîtrise du processus de fabrication nous permet de mettre en œuvre les conditions pour vous fournir des produits d’équipements de traitements des eaux conformes à vos exigences.

Précision, gains de productivité et baisse des coûts

Travail de finition hautement configurable et personnalisable

Qualité et conformité CE assurées par le montage et tests pré-livraison

Exclusivement composé d'ingénieurs, notre bureau d'étude fort de son expertise, vous guide dans le choix de vos équipements. Depuis 30 ans, un énorme focus sur la Recherche et Développement nous permet de vous offrir des machines efficaces, robustes, simples et économiques.

Nos compétences pluridisciplinaires (génie des procédés, hydraulique, automatisme, mécanique, traitement des eaux) nous permettent de vous apporter une vision globale du fonctionnement de chaque équipement suivant vos attentes. Un guichet unique "one-stop-shop" pour toutes vos questions.

La conception assistée par ordinateur (CAO 3D) est un outil puissant pour réaliser des modélisations géométriques de qualité et de précision. Cela nous permet d'élaborer, de visualiser et de partager des concepts machines et implementations afin de répondre au mieux à vos besoins.

Réactivité grâce à notre stock et fabrication de pièces de rechange

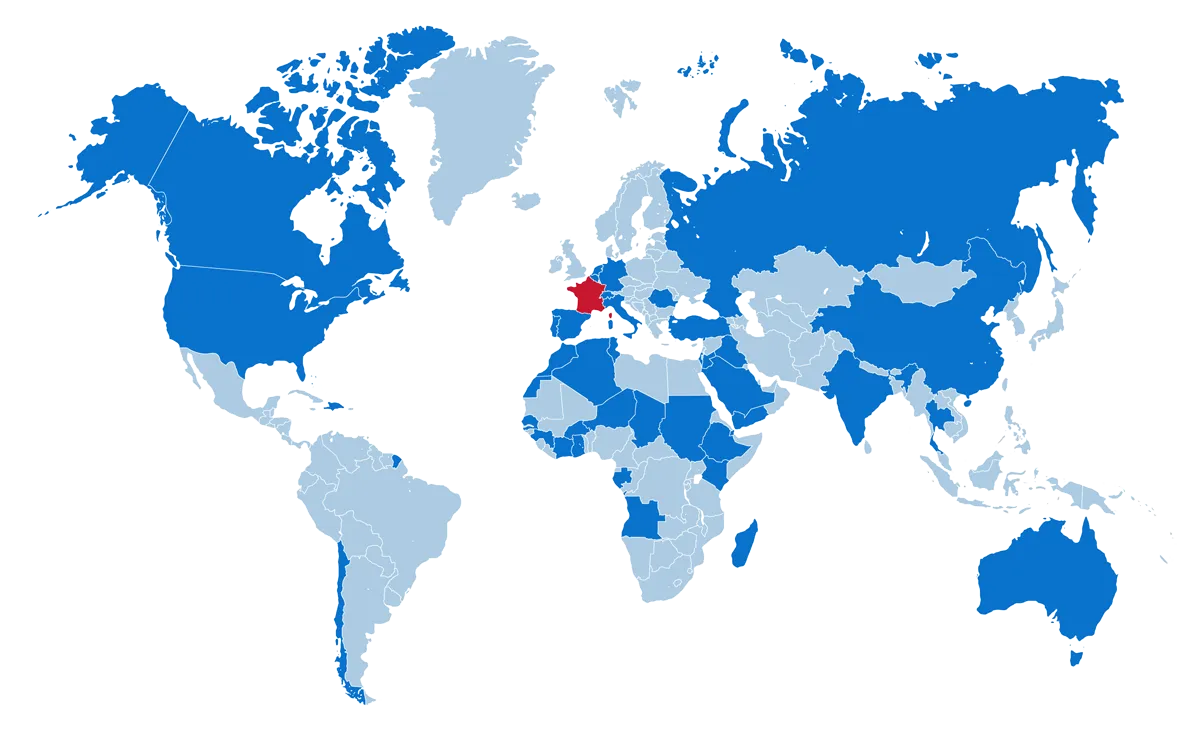

Équipe pouvant intervenir rapidement sur toute la France

| Cookie | Durée | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |